US research project: Strategic Highway Research Programme (SHRP2)

Client

BAM – Bundesanstalt für Materialforschung und -prüfung

Project tasks

Comparison of inspection methods

Measurements

- SPACETEC TS3

- Total length 3,2 km

The project in detail

The Chesapeake Bay (Maryland and Virginia) is connected by a 37-kilometre long bridge-tunnel system between Virginia Beach and the Delmarva peninsula. This system connects two tunnels (Thimble Shoal and Chesapeake) and various bridges with four artificial islands.

The two-lane, immersed-type concrete Chesapeake Tunnel was lowered into a trench at the bottom of the Chesapeake Bay and opened to traffic in 1964. The tunnel surface is, like most of the tunnels in the U.S., covered with ceramic tiles.

On behalf of the Federal Institute for Materials Research in Berlin (BAM) the Chesapeake Tunnel survey was performed with the SPACETEC TS3 laser scanner as part of the SHRP2 program.

In this research project, various contact and contactless measurement methods were compared for assessing the tunnel lining conditions.

Measurements

Well-defined thermographic conditions are necessary for screening the tunnel linings. In this specific case these conditions could be met at the time of survey.

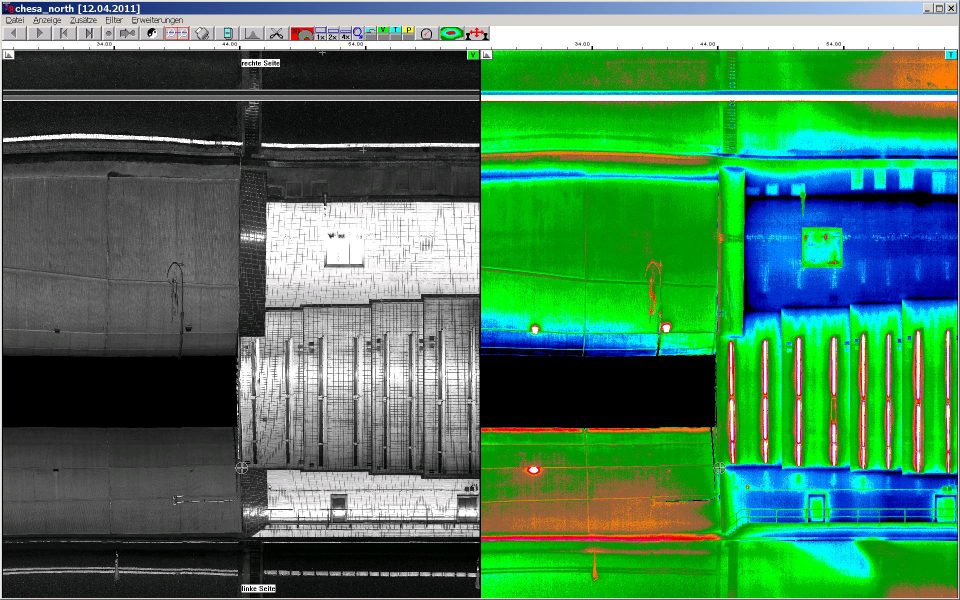

Only one lane was closed for traffic during the survey, so the recording was performed twice — once driving in the southbound lane and a second time in the opposite northbound lane. This caused only a minor effect on traffic flow. The scanner was mounted on the roof of a vehicle, which enabled unobstructed, 360-degree measurement.

Data analysis

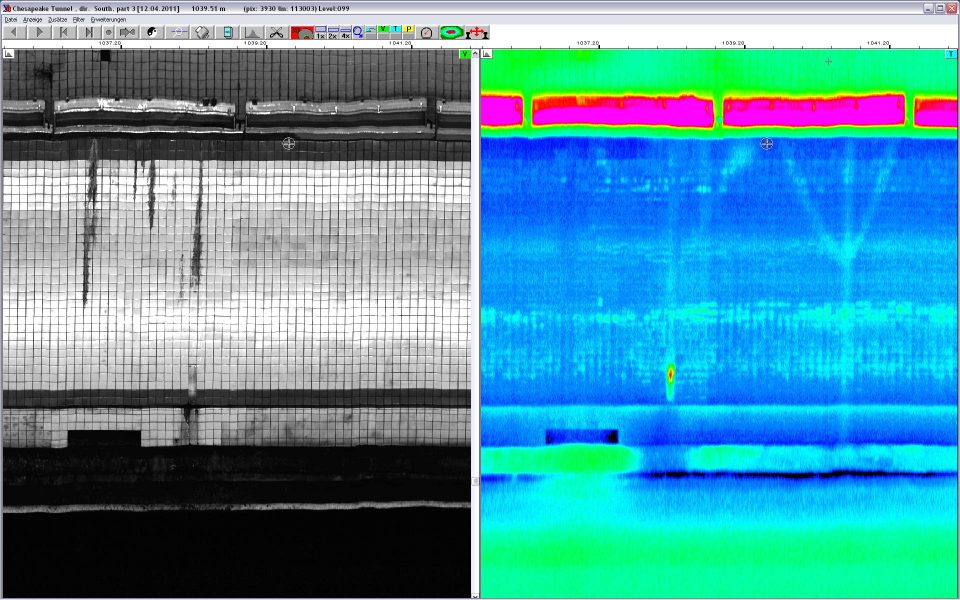

Structural damage such as loose tiles, cracks and other findings, e.g. thermal anomalies, were detected and mapped on the screen with TuView.

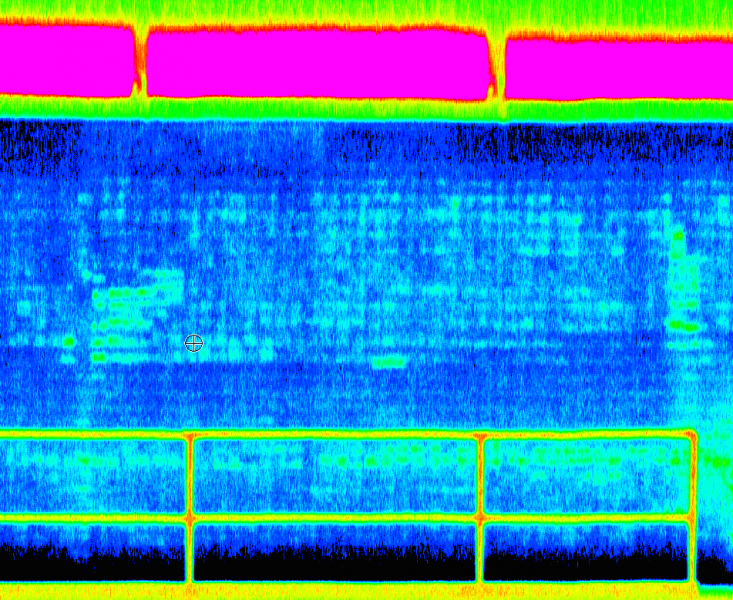

Drainage systems and supply pipes behind the surface were detected by the thermal data channel. The detachment of ceramic tiles from the concrete tunnel surface results in a modified thermal conductivity. Loose tiles which were poorly attached to the tunnel wall stood out in the thermal scans as areas of warmth due to an altered heat conductivity and could be verified by tapping with a hammer.

However, some areas which did not show evidence of surface damage but which did appear warmer in the thermography were further investigated using ultrasonic tomography (UST).

UST measures the pulse rate and pulse attenuation of shear waves due to defects in the material using an array of transducers mounted on the tunnel wall.

Using this method, a potentially shallow, detached area above the reinforcement mesh was revealed at a depth of approximately 10 centimetres. The area of detachment in the UST corresponded with the thermal anomaly.

The SPACETEC laser scanner provided surface covering recordings of the tunnel linings in just a short period of time with minimal restriction of traffic flow. The findings of the SPACETEC laser scanner recordings have established the foundation for more detailed investigations with other measurement methods.